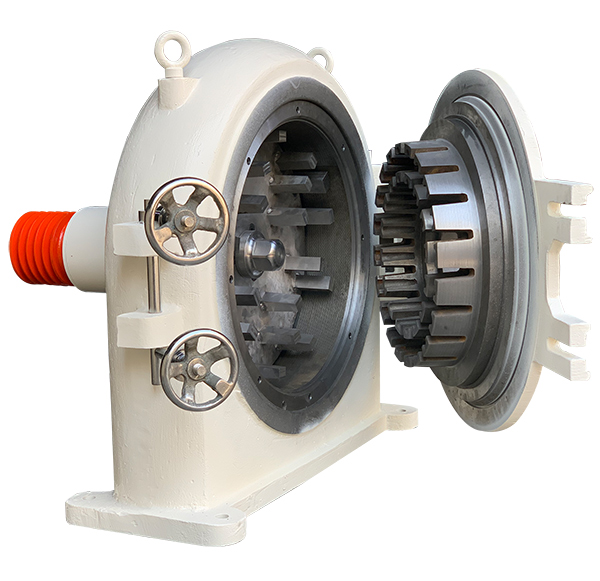

An "SS pin mill machine" is a pin mill machine that is made out of stainless steel (SS). Due to its resistance to corrosion, durability, and simplicity of cleaning, stainless steel is frequently utilised in the production of food processing and pharmaceutical equipment.The device I previously mentioned in my response is still referred to as a "pin mill machine". It is a kind of material-reduction device that is utilised in many sectors to reduce the size of materials.

We are prominent manufacturer and supplier of ss pin mill machine that are provided with most modern features.A rotor or disc with rotating pins or blades powers the operation of the SS pin mill machine. The processing materials are inserted into the machine's grinding chamber where they come into contact with the spinning pins. The crashes and high-speed interactions between